HSK Hybrid G1 Chuck

Guarantee of 3μm of integrated runout accuracy

For standard model with the collet chuck, 3μm of integrated runout accuracy is guaranteed.

Easy operation of collet holder with higher precision than that of shrink-fit holder

HSK Super G1 chuck adopts collet holder system, and has the same or better runout accuracy as that of the shrink-fit holders, not requiring any other special equipment such as heating device, much curtailing the tool changing time.

Usable up to 50,000min-1

Simple and straight outside appearance, having no space of the locknut, controls to minimize the aerodynamic noise and cutting fluid dispersion. Small-sized locknut enables minimizing the floating affection to the balancing.

HSK Super G1 Chuck

Guarantee of 5μm of integrated runout accuracy

As the integrated runout with the collet, the standard model guarantees 5μm of accuracy.

Strong Gripping Force

The double taper-collet system ensures stronger grip torque than that of a single taper collet.

Super balancing, most suitable for high speed cutting

Grinding of the external surface of the holder secures a high balancing.

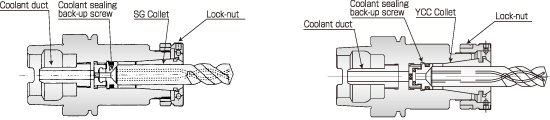

Usable for operation with high-pressure coolant.

With a coolant seal screw, the holder can be used for operation with a high pressure spindle-through coolant up to 7.0 MPa (70kg/cm3).

HSK New Drill Mill Chuck

Squeezing of 1mm per one collet.

YCC drill mill collet can squeeze up to 1mm, but depending on the capacity.

High rigidity and high accuracy

Distinguished in rigidity at the thickened collet-inserting section of the holder and minimized uneven accuracy.

Super balancing

Grinding of the external surface of the holder secures a high balancing.

Available for high-pressure coolant

Set a coolant seal screw and it will be available for high- pressure spindle coolant up to 7.0MPa.

Drawing of holder using high pressure coolant

HSK Duplex-Holding Holder

HSK Duplex-Holding Holder

page top

page top