EY Tooling Collet

EY Tooling Collet- Features/Specifications

- EY Collets (European type:Taper8°)

- EY Chucks with S20T Shank

- EY Chucks with BT30 Shank

- EY Floating Reamer Holder

- EY Chucks with Straight Shank

- EY Chucks with Straight Shank

for CNC Lathe - EY Tool Change Adapters

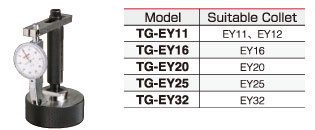

- Tool Pre-setters for

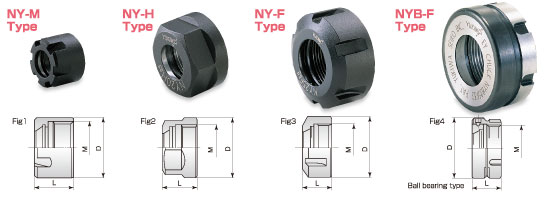

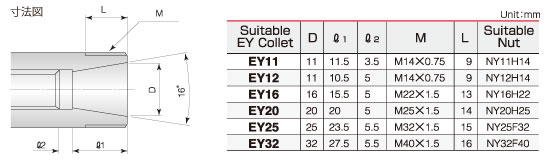

EY Tool Change Adapters - NY Lock Nuts

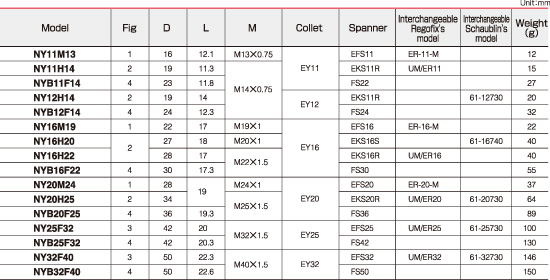

- Spanners

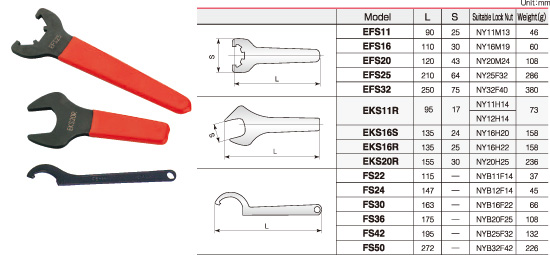

- Tapping Collets

- Coolant-Sealing Back-up Screws

- Taper Gauge

- Spindle Nose

- << Previous page

NY Lock Nuts

Spanners

Tapping Collets

How to use

The following programming for tapping process is remmended:fast approach to the work piece, then tapping feed with approximately 95% of the pitch value, which is 20-30% of the compensation stroke(E), when the spindle rotation and feed movement are simultaneously reversed. Return feed must be made with 100% of the pitch, which maintains the sleeve of tapping collect in compensation stroke up to the tap disengagement;quick return can then be programmed with usual stroke security. The relatively long axial compensation assists easy programming. When tapping with very high speed, an appropriate programming compensation may be necessary to balance the differences of inertia between the spindle and the feed movement on reverse.

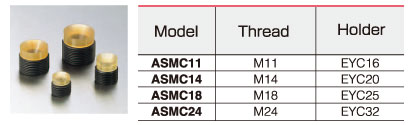

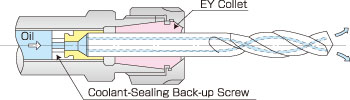

Coolant-Sealing Back-up Screws

For the drills having oil holes for coolant, being used to the EY chucks, this coolant-sealing back-up screw can be used in place of the standard back-up screw, for sealing the coolant oil coming from the rear side.

Applicable for oil-coolant drills having a more than 5mm diameter hold

These Coolant Sealing Back-up Screws are capable of sealing for oil-coolant drills having hole diameter 5 to 32mm.

Taper Gauge

Spindle Nose

Reference dimensions for the customers in designing the spindle by themselves. Further details shall be inquired to us.

page top

page top