Since small diameter end mills(especially made of solid carbide) are easy to break during working, they are required to be highly precise in the chucking. The pencil mill chuck is an end mill holder specially developed to ensure this ultra high precision chucking for small end mills, attaining an incomparable high accuracy in the chucking.

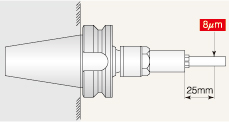

High precision Runout within 8μ

Adopting the drawback collet, even the standard type guarantees the runout accuracy of

within 8μ at 25mm distance from the holder's

head.

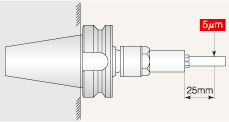

Super precision type (Special specification) Runout within 5μ

Super precision type guarantees the runout

accuracy to be within 5μ at 25mm distance

from the holder's head. For the super precision

type, please order the holder with the collet

having been set in together.

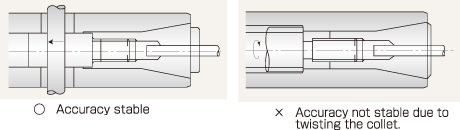

Method to secure a stable high precision

The conventional method to chuck the tool by

the drawback type collet is to screw-in the threaded draw-bar which will also cause twisting of

the collet and, accordingly, deteriorate the

accuracy. The pencil mill chuck draws the collet

straight without screwing the draw-bar without

the collet being twisted, which will keep the

accuracy to be stable.

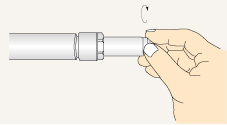

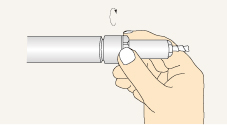

How to set the collet and tool

1)Hold the square part of the collet's end and

insert the collet into the holder.

2)Insert the tool into this collet and turn the lock

nut in CW direction by hand to be locked.

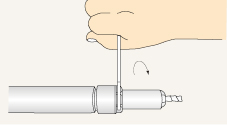

3)Tighten the lock nut with a spanner.

(The spanner is a special accessory.)

Can be used for a high speed cutting

Since each part of the pencil mill chuck is precisely made and is assembled well balanced, the chuck can be used for a precision cutting work without vibration even over 20,000min-1 of high speed cutting.

Easy tool chucking

The tool can be chucked easily only by tightening the lock nut in CW direction. The tool change as well as the collet change can be done only from holder's head end.

Slim head

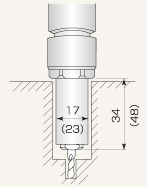

he pencil mill chucks have two types. One is

PCH6 for collet capa. of 3, 4 and 6mm, the

other is PCH10 for collet capa. of 3, 4, 6, 8,

and 10mm. Head diameter of PCH6 is 17mm

and that of PCH10 is 23mm. These slim heads

will prevent unnecessary collision with the

workpiece and enable the tip of the end mill

well visible, all of which will eventually

improve the operation efficiency.

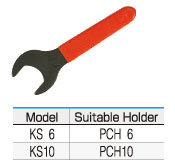

Spanners (Separate accessory)

Pencil Mill Chucks

Pencil Mill Chucks

page top

page top